ABG 1040/ 1030

| Spray Nozzle | Type | ABG |

| Spray Type | Airborne | Air Atomizing |

| Liquid orifice size range ( Standard) | mm | 0.8 – 1.5 , (1.0) |

| Solution Flow Rate ( typical per gun ) | Liter/ hr | 6-30 |

| Atomizing Air Pressure | bar | 0.7 - 3 |

| Spray width pressure range | bar | 1.0 – 4.0 |

| Maximum Compressed air pressure | bar | 5.5 |

| Compressed air consumption ( max at 2 bar ) | Nm 3 /hour | 10.5 |

| Seal Material Standard Approvals | FDA | Approved |

ABG 2030 / 2040

| Spray Nozzle | Type | ABG |

| Spray Type | Oval Flat | Air Atomizing |

| Liquid nozzle orifice size | mm | 0.8 – 1.5 , (1.0, 1.2) |

| Flow Rate (For Coating Application) | gm/ min | 20 - 150g/min |

| Atomizing Air Pressure | bar | 0.7 - 3 |

| Spray Angle | deg | 10 – 60 deg |

| Maximum Compressed air pressure | bar | 5.5 |

| Compressed air consumption ( @ 2 bar ) | Nm 3 /hour | 10.5 |

| Seal Material Standard Approvals | FDA | Approved |

ABGS

| Spray Nozzle | Type | ABGS |

| Spray Type | Airborne | Air Atomizing |

| Liquid orifice size range ( Standard) | mm | 0.5 – 1.5 , (1.0) |

| Solution Flow Rate ( typical per gun ) | Liter/ hr | 3.5-19 |

| Atomizing Air Pressure | bar | 0.7 - 3 |

| Spray width pressure range | bar | 1.0 – 4.0 |

| Maximum Compressed air pressure | bar | 5.5 |

| Compressed air consumption ( max at 2 bar ) | Nm 3 /hour | 10.5 |

| Seal Material Standard Approvals | FDA | Approved |

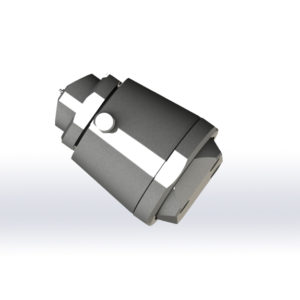

ABH – 1040/ 1030

| Spray Nozzle | Type | ABH |

| Spray Type | Airborne | Air Atomizing |

| Liquid orifice size range ( Standard) | mm | 0.5 – 1.5 , (1.0, 1.2) |

| Solution Flow Rate ( typical per gun ) | Liter/ hr | 50g/min- 178g/min |

| Atomizing Air Pressure | bar | 0.7 - 3 |

| Angle | @ 2 Bar | 60 degree |

| Maximum Compressed air pressure | bar | 5.5 |

| Compressed air consumption ( max at 2 bar ) | Nm 3 /hour | 11.5 |

| Seal Material Standard Approvals | FDA | Approved |

ABH 2030/ 2040

| Spray Nozzle | Type | ABH |

| Spray Type | Airborne | Air Atomizing |

| Liquid orifice size range ( Standard) | mm | 0.5 – 1.5 , (1.0, 1.2) |

| Solution Flow Rate ( typical per gun ) | Liter/ hr | 50g/min- 178g/min |

| Atomizing Air Pressure | bar | 0.7 - 3 |

| Angle | @ 2 Bar | 60 degree |

| Maximum Compressed air pressure | bar | 5.5 |

| Compressed air consumption ( max at 2 bar ) | Nm 3 /hour | 11.5 |

| Seal Material Standard Approvals | FDA | Approved |

ABH-3000

Fully integrated manifold designed specifically for tablet coating applications with ABH high performance spray gun. Easy to install in any coater to modernize with upmost technology available in market. Made with Titanium/ SS 316L to reduce weight & increase durability. Fast dismantling & assembling allowing arm to put back in service faster. Smart piping with all close loops & sanitary arrangement.

SAG

- Uniform spray distribution

- Shut of needle with pneumatic actuator

- Anti - Bearding ( Non Clogging ) designed spray Nozzle Assembly

- Anti Dripping

- Liquid Flow adjustment

- Easy to clean – User Friendly

- Low Maintenance

- Easy to Install

- Unique Pan Pattern with angle adjustment option

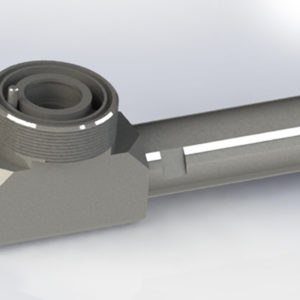

Wurster Coating Spray Gun

Fluid Beds are very versatile machines that allow you to run an array of different processes like drying, granulation and coating to name a few. For fluid bed nozzles, Pharma Spray Solutions offers complete spray lances for both top spray and bottom Wurster spray for pilot or production scale and also single nozzles for tangential spray applications. Whether you have a new machine or retrofit requirement, requirements of spare parts for existing units or questions regarding spray set up and troubleshooting, Pharma Spray Solutions can help with all your spraying requirements for fluid bed applications.